Bowers & Wilkins 800 Diamond D3 - Continuum Membrane

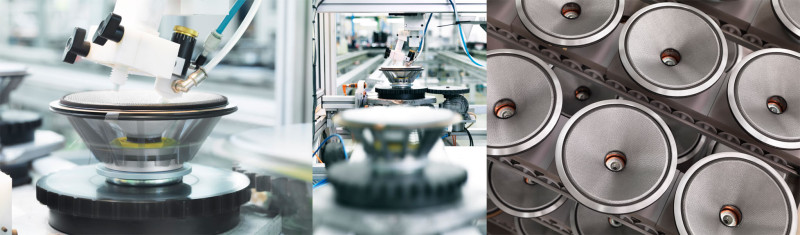

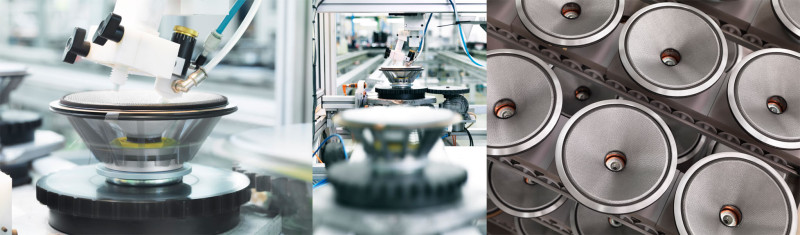

For more than 40 years, Bowers & Wilkins has been using Kevlar as the cone material for the midrange drivers in its speakers. During this time, this technology has been continuously developed and improved. Nevertheless, the engineers at B&W have always explored other materials as well, in order to further enhance the performance of their products. In 2007, they achieved an interesting development, which they continued to research for the next eight years. During this period, over 70 different prototypes with this new material were created. The result of this development is the new Continuum cones, which are being used for the first time in the 800 Diamond D3 series. Just like the Kevlar cones, the new Continuum drivers are based on the same findings about controlled cone break-up at the limit. Theoretically, an infinitely rigid material would be the best choice for a speaker cone. The movements of the magnetic drive would then be converted evenly into air vibrations across the entire cone surface. In practice, however, such a material does not exist, and every speaker cone tends to deform and virtually "break up" when it reaches its own resonant frequency. The result is tonal coloration and distortion. With cones made of Kevlar fabric, B&W has been taking a different approach for decades. Instead of fighting the inevitable break-up, the fabric and shape of the cone have been developed so that the resonance vibrations occur in a controlled manner and influence the sound as little as possible. B&W has now further improved this principle with the Continuum drivers. Here, too, a stable, coated fabric is used, which can reduce and control break-up even more effectively. The result is an unsurpassed, coloration-free sound. Martial Rousseau, Head of Research and Development at B&W, compares the step from Kevlar to Continuum cones to the step from aluminum to diamond tweeters ten years ago. To control this advanced technology and ensure consistently high quality in mass production, Bowers & Wilkins had only one choice. Like the Kevlar drivers, the Continuum drivers are now also manufactured from supplied components in their own factory in Worthing. This allows B&W to draw on the decades of experience of its employees and produce speaker drivers that meet the demands of the new 800 Diamond series.